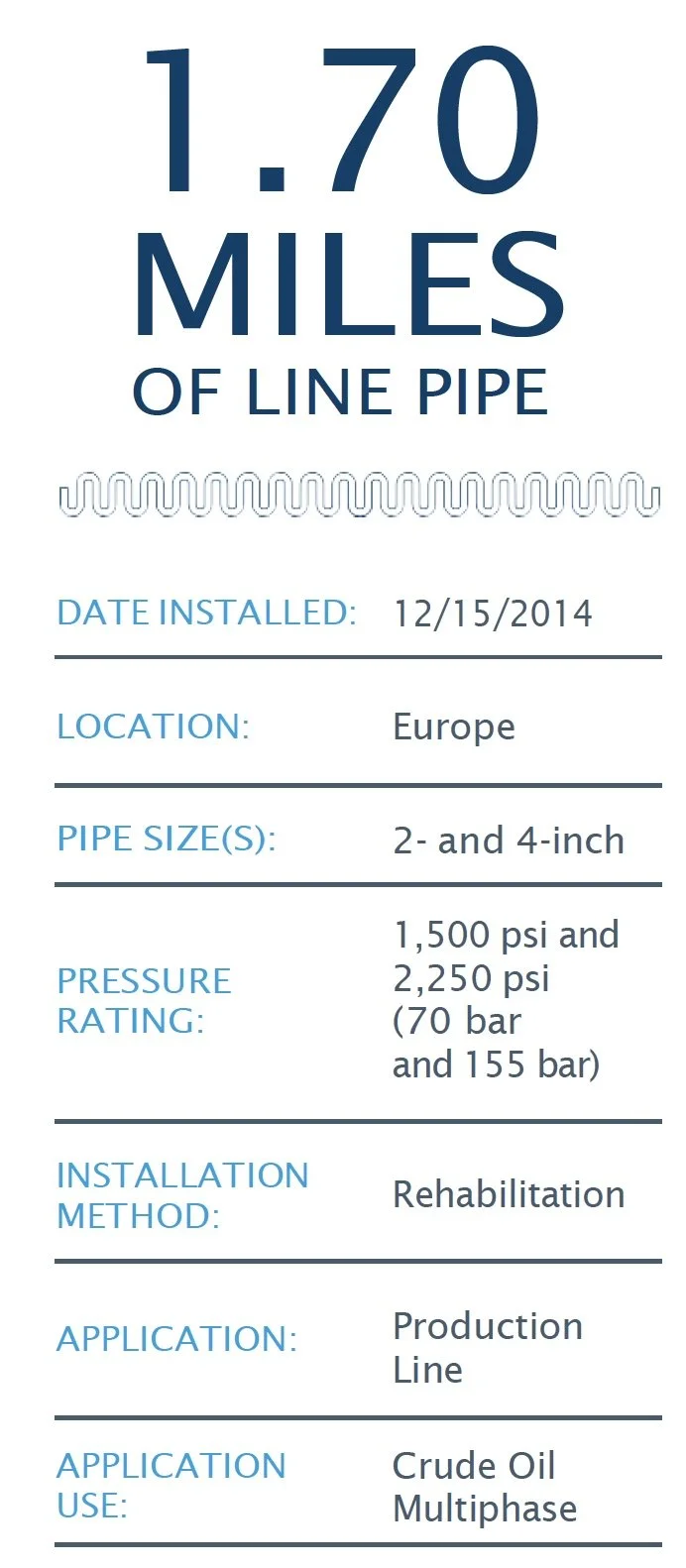

Steel-reinforced Pipe Enables a Dual-line 1.12 Mile Pull for a 7-day Pipeline Rehabilitation in Europe

The Challenge

Aging pipelines in service off the southern coast of Sicily forced an oil and gas company to deal with corrosion-related line damage. The company needed a safe and cost- effective solution to rehabilitate a damaged 12-inch multiphase pipeline consisting of a 1.12-mile (1.8-km) offshore section and a .50-mile (.81-km) onshore section.

The Solution

Working together with the company, FlexSteel developed a rehabilitation plan to use the eroding steel multiphase pipeline as a casing. FlexSteel would pull a 1.12-mile (1.8-km) dual pipeline consisting of its 2-inch, 1,500 psi (70 bar) pipe and 4-inch, 2,250 psi (155 bar) pipe for the offshore section. In a second operation, a .50-mile (.81- km) dual pipeline of the same sizes would be pulled through the onshore section of the multiphase line.

With other spoolable pipe products, an approach that calls for pulling two lengthy sections of pipe in single pipe-in-pipe operations might seem risky. However, FlexSteel’s durable steel-reinforced design and superior tension capabilities would make this an extremely efficient and reliable solution for the company. In addition, the anti-corrosive properties of the two FlexSteel lines would substantially increase the pipeline’s service life, eliminating the inspection and maintenance downtime associated with corrosion issues that are often experienced after installing steel pipelines.

The Result

The structural integrity of FlexSteel’s pipe provided a quick, easy-to-install solution that restored the aging pipeline in only seven days. The pipeline system and connections manufactured by FlexSteel were all hydrotested twice: once at the manufacturing facility and again at the project site. The collaboration between the company and FlexSteel resulted in a project that was completed efficiently while operational risks were mitigated.