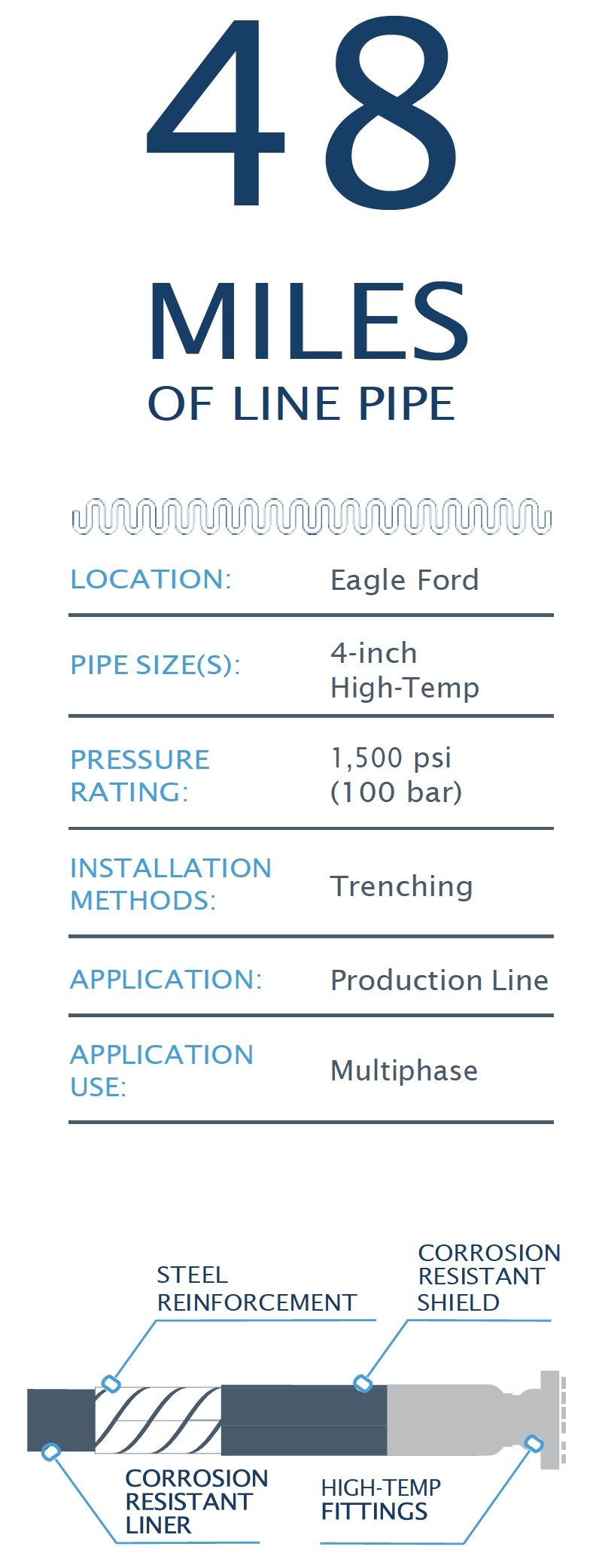

Spoolable Steel-reinforced Pipe’s Performance Leads E&P Company to Install 48 Miles in Eagle Ford Shale

The Challenge

After experiencing numerous multiphase production pipeline failures in the Eagle Ford Shale of Texas, an E&P company was forced to decommission several pipeline systems, severely limiting its ability to recover hydrocarbon assets in the area. It was determined that in high-temperature applications, the fiberglass pipe that was being used for the company’s multiphase line was prone to liner collapse. This put excessive stress on the pipe’s connectors, which caused them to suffer a loss of sealing integrity. Accordingly, the operator needed a safe and reliable replacement pipeline to restore the hydrocarbon transmission capacity of the lines. While many line pipe solutions were considered, the company’s application demanded a pipeline system capable of tolerating the high-temperature operating conditions in the region.

The Solution

Working closely with the company, FlexSteel developed a plan to replace the damaged lines with a more reliable pipeline system. Based on its ability to withstand temperatures up to 194°F (90°C) and pressure ratings up to 3,000 psi (200 bar), FlexSteel recommended its High-Temp 4-inch line pipe. Beyond its tolerance for higher temperatures, FlexSteel’s line pipe can be delivered in longer lengths, requiring fewer connectors for safer and faster installation. In addition, the pipe is not subject to derating in higher temperature applications. The pipeline replacement plan also included the use of FlexSteel’s high- temperature connectors, which are designed to combat the effects of corrosion at higher temperatures.

The Result

The company’s new pipeline system was installed by FlexSteel in an operation that was much safer and faster than alternative pipe technologies. This system enabled the company to regain its original hydrocarbon transmission capacity in the shortest time possible. The company also obtained a pipeline with a substantially greater tolerance for high temperatures to endure operational conditions. Based on this experience, the company has installed approximately 48 additional miles of FlexSteel High-Temp line pipe in the Eagle Ford Shale. In addition, the company has indicated that larger volumes of FlexSteel’s High-Temp pipe will be needed for future projects in other harsh application areas.